Markal Thermomelt Heat Stik

Thermomelt

Please note that the color of the Thermomelts are not a part of their function, since the temperature signal consists of melting. Indicator color is subject to change without notice.

Thermomelt

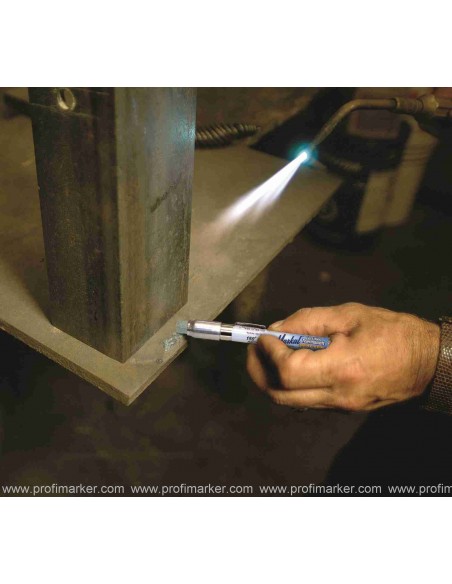

Thermomelt HEAT-STIK markers are a quick, low-cost method to accurately measure surface temperatures of various metals and equipment. Available in 88 Fahrenheit and 32 Centigrade temperatures, the stick-in-holder design provides convenience and durability for long-lasting use in the workshop or in the field.

Please note that the color of the Thermomelts are not a part of their function, since the temperature signal consists of melting. Indicator color is subject to change without notice.

FEATURES & BENEFITS

When the stick melts, the precise temperature is reached

Long-lasting stick is 33% bigger than competition

Accurate to within +/- 1% of Fahrenheit and +/- 3% Celsius rated temperatures; no need for sensor calibration

Ideal for: pre-heating, post-weld heat treating, interpass temperature monitoring, stress-relieving and annealing

Protective holder, shirt-clip and adjustment ring prevents breakage and improves handling

For low corrosion (low chlorides/halogens) applications, see Thermomelt - Low Corrosion Temperatures

Meets welding codes: AWS D1.1, ANSI/ASME Code B32.1 & B31.3, ASME Code Sec. I, III, and VII, NIST Traceable

Made in U.S.A.

INDUSTRY USES:

Welding

Ship building and repair

Bridge fabrication

Metal fabrication

Forge and casting foundries

Railroad industry

Steel mills and warehouses

SURFACE USES:

Steel and iron

Details:

86400 100ºF (38ºC)

86409 109ºF (43ºC)

86418 113ºF (45ºC)

86427 119ºF (48ºC)

86436 125ºF (52ºC)

86445 131ºF (55ºC)

86454 138ºF (59ºC)

86463 150ºF (66ºC)

86472 163ºF (73ºC)

86481 175ºF (79ºC)

86490 182ºF (83ºC)

86499 188ºF (87ºC)

86508 194ºF (90ºC)

86517 200ºF (93ºC)

86522 206ºF (97ºC)

86526 213ºF (101ºC)

86535 219ºF (104ºC)

86544 225ºF (107ºC)

86553 238ºF (114ºC)

86562 250ºF (121ºC)

86569 256ºF (124ºC)

86571 263ºF (128ºC)

86580 269ºF (132ºC)

86589 275ºF (135ºC)

86598 282ºF (139ºC)

86607 288ºF (142ºC)

86616 294ºF (146ºC)

86625 300ºF (149ºC)

86634 306ºF (152ºC)

86643 313ºF (156ºC)

86652 319ºF (159ºC)

86661 325ºF (163ºC)

86670 331ºF (166ºC)

86679 338ºF (170ºC)

86688 344ºF (173ºC)

86697 350ºF (177ºC)

86706 363ºF (184ºC)

86715 375ºF (191ºC)

86724 388ºF (198ºC)

86733 400ºF (204ºC)

86742 413ºF (212ºC)

86751 425ºF (218ºC)

86760 438ºF (225ºC)

86769 450ºF (232ºC)

86778 463ºF (239ºC)

86787 475ºF (246ºC)

86796 488ºF (253ºC)

86805 500ºF (260ºC)

86814 525ºF (274ºC)

86823 550ºF (288ºC)

86832 575ºF (302ºC)

86841 600ºF (316ºC)

86850 625ºF (239ºC)

86859 650ºF (343ºC)

86868 700ºF (371ºC)

86877 750ºF (399ºC)

86886 800ºF (427ºC)

86895 850ºF (454ºC)

86904 900ºF (482ºC)

86922 950ºF (510ºC)

86931 1000ºF (538ºC)

86940 1022ºF (550ºC)

86949 1050ºF (565ºC)

86958 1100ºF (593ºC)

86967 1150ºF (621ºC)

86976 1200ºF (649ºC)

86985 1250ºF (677ºC)

86994 1300ºF (704ºC)

87003 1350ºF (732ºC)

87012 1400ºF (760ºC)

87021 1425ºF (774ºC)

87030 1450ºF (788ºC)

87039 1480ºF (804ºC)

87048 1500ºF (816ºC)

87057 1550ºF (843ºC)

87066 1600ºF (871ºC)

87075 1650ºF (899ºC)

87084 1700ºF (927ºC)

87093 1750ºF (954ºC)

87102 1800ºF (982ºC)

87111 1850ºF (1010ºC)

87120 1900ºF (1038ºC)

87129 1950ºF (1066ºC)

87138 2000ºF (1093ºC)

87147 2050ºF (1121ºC)

87156 2100ºF (1149ºC)

87165 2150ºF (1177ºC)

87174 2200ºF (1204ºC)

86402 50ºC

86404 75ºC

86401 100ºC

86408 125ºC

84664 150ºC

86410 175ºC

86516 200ºC

86405 225ºC

86563 250ºC

86407 275ºC

86626 300ºC

86698 350ºC

86734 400ºC

86770 450ºC

86807 500ºC

86824 550ºC

86842 600ºC

86860 650ºC

86870 700ºC

86878 750ºC

86887 800ºC

86896 850ºC

86905 900ºC

86923 950ºC

86932 1000ºC

86960 1100ºC

- Oberfläche des Materials

- glatt

poliert

porenfrei

sauber - Anwendungsgebiet

- Bahnindustrie

Brückenbau

Gisserei und Schmiede

Metallverarbeitung

Schiffbau und Reparatur

Schweissen

Stahlwerke und Stahlhandel - Eignung für

- Eisen

Stahl